PLASTIC PACKAGING

IN-HOUSE PLASTIC PACKAGING PRODUCTION

All the plastic canisters are being produced by the factory itself since a new plastic packaging department was opened in 2012. There are 10 production lines for different volumes: 1 L, 4 L, 5 L, 7 L, 10 L and 20 L.

It all starts with mixing masterbatch with high-quality HDPE polyethylene. German-made dosators by Motan Colotronic guarantee the most precise proportion of paints and base materials, therefore each canister looks absolutely like one another.

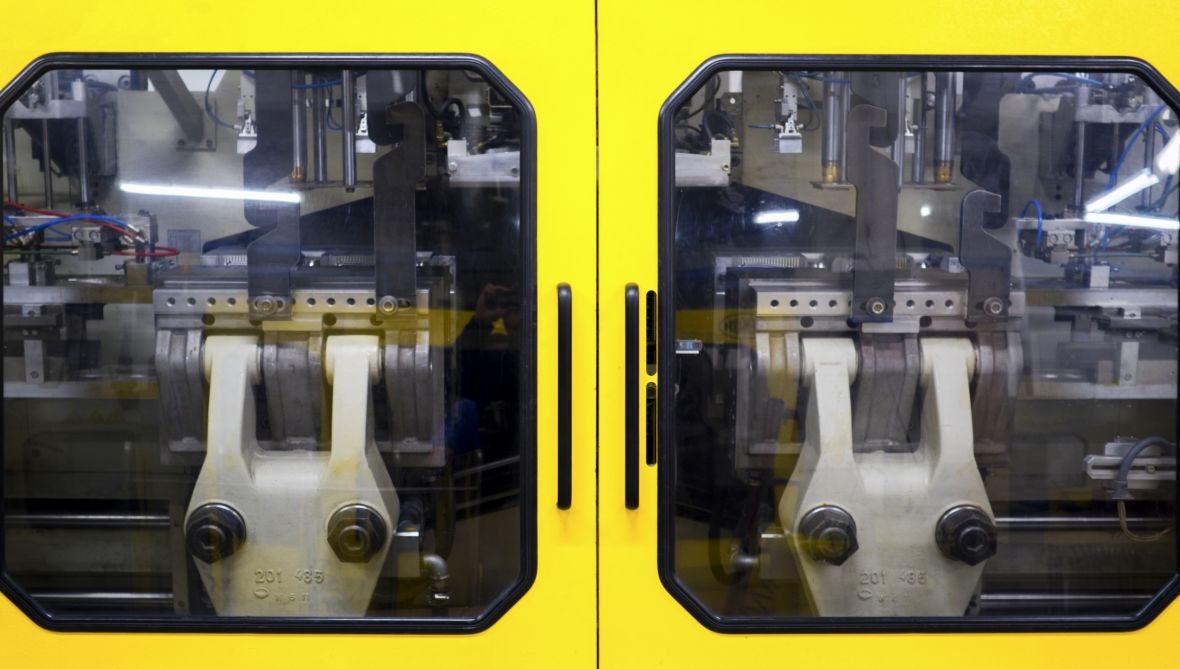

The next step is to form the canisters. Currently there are 6 lines of the German brand BECUM which all together produce over 6,000 FANFARO canisters each day. Polyethylene and green masterbatch are weighed and then proceed towards the heating element, where they melt and mix into a homogeneous substance.

Special extractors squeeze the melted substance through nipples, and then the cooling press closes around to form a canister.

Over 150,000 canisters are always kept in stock in the warehouse.